- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

Brand Name : Powerbuilder

Model Number : PB-30

Certification : CE ISO13485 ISO9001

Place of Origin : China

MOQ : 1

Price : USD 12000-25000 pieces

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 1000 pieces per year

Delivery Time : 40 days

Packaging Details : Wooden Case

Capacity : 30Nm/h

Outlet Pressure : 4~5.5bar Adjustable

Filling pressure : 150Bar or 200 Bar

Size : 1800*1000*2300 1400kg

93% Purity 30Nm3/H Psa Oxygen Generator/Psa Oxygen Gas Generator/Oxygen Gas Generator/

Description for PSA Oxygen Generator

PSA Oxygen Generator is consisted of the screw air compressor, air dryer, filters, buffer tanks, oxygen generator, electricity control system and the optional oxygen cylinder filling station. The complete system is installed and tested at factory, delivery to customer's turn-key project.

PB containerized oxygen generator is removable, and makes the onsite installation and operation very easy. It can also save the cost for the decoration cost of the machine room.

Main Features for PSA Oxygen Generator

PB PSA Oxygen Generator Model Select

| Range of the PSA Oxygen Generator | |||||||

| Model | O2 Flow (Nm3/h) | O2 Flow (LPM) | Equivalent cylinder-7m3(per day Nos) | Power With booster(Kw) | Power Without HPBC(Kw) | Purity | Loading |

| PB-5 | 5 | 83 | 17 | 13 | 9 | 93%±3% | LCL |

| PB-10 | 10 | 167 | 34 | 22 | 16.5 | 93%±3% | LCL/20GP |

| PB-15 | 15 | 250 | 51 | 28 | 20.5 | 93%±3% | LCL/20GP |

| PB-20 | 20 | 333 | 68 | 43 | 32 | 93%±3% | 20HQ/40HQ |

| PB-25 | 25 | 417 | 85 | 43 | 32 | 93%±3% | 20HQ/40HQ |

| PB-30 | 30 | 500 | 102 | 55 | 40 | 93%±3% | 20HQ/40HQ |

| PB-40 | 40 | 667 | 136 | 63 | 48 | 93%±3% | 40HQ |

| PB-50 | 50 | 833 | 170 | 76 | 57.5 | 93%±3% | 40HQ |

| PB-65 | 65 | 1083 | 221 | 101 | 79 | 93%±3% | 40OT |

| PB-80 | 80 | 1333 | 272 | 145 | 115 | 93%±3% | 40FR |

| PB-90 | 90 | 1500 | 306 | 181 | 144 | 93%±3% | 40FR |

| PB-100 | 100 | 1667 | 340 | 214 | 177 | 93%±3% | 40FR |

| PB-120 | 120 | 2000 | 408 | 247 | 203 | 93%±3% | 40FR+20GP |

| PB-150 | 150 | 2500 | 510 | 263 | 218 | 93%±3% | 40FR+20GP |

Working Principles for PSA Oxygen Generator

| PB-30 PSA Oxygen Plant Technical Specification | ||||||

| lot | Item | Description /Specification | ||||

| 1 | Model/Place of Manufacture | PB-30 | China | |||

| 2 | Oxygen making principle | PSA Pressure swing adsorption PSA变压吸附(开放式结构) | ||||

| 3 | Application | Operation place | Indoor | |||

| Environment | Ambient temperature | Min -5℃/Max 50℃/ design temperature37℃ | ||||

| Ambient humidity | Min 40%RH Max90%RH | |||||

| 4 | Capacity | 30 | Nm3/hr | |||

| 5 | Oxygen Gas Purity | 93% ±3% Test at outlet of psa oxygen generator | ||||

| 6 | Oxygen Purity Sensor | HT-TA530 1set | ||||

| 7 | Oxygen Flowmeter | Japan SMC flowmeter 1 sets | ||||

| 8 | Inlet compress air pressure | 0.55~0.7 Mpa | ||||

| 9 | Inlet Oil Content | ≤0.001mg/m3 | ||||

| Residual dust | ≤0.01um | |||||

| Residual water | ≤0.069mg/m3 | |||||

| 10 | Air inlet atmospheric dew point | -15℃ | ||||

| 11 | Demand for clean compressed air | 6.5 m³/min | Recommend Air compressor | 37Kw 6.8 m³/min 8Bar | ||

| 12 | Inlet Diameter | DN40 | ||||

| 13 | Outlet Diameter | DN15 | ||||

| 14 | Maximum inlet temperature | MAX 30 ℃ | ||||

| 15 | Allowable working pressure range | Min7.5Kgf / cm2 Max9.9Kgf / cm2 | ||||

| 16 | Carbon molecular sieve model/origin | JLOX-500 | ||||

| 17 | The tower body pipe | 2 sets | ||||

| 18 | Air and Oxygen buffer tank | Piped storage tank | ||||

| 19 | Instrument Tank, silencer | PB Silencer ≤55dB(A) | ||||

| 20 | Solenoid valve brand/origin | AirTAC | 9 sets | |||

| 21 | Pneumatic valve brand/origin | Powerbuilder | 9 Sets+2 Sets | |||

| 22 | Control System | Control Power Supply | 0.2kw/set 220V 50 HZ | |||

| PLC | Siemens PL Smart S7-200 or Mitsubishi integrated PLC | |||||

| Electrical box | built-in | 1 set | ||||

| Touch screen | MCGS 7 inch or Mitsubishi integrated PLC with screen | |||||

| 23 | size LxWxH (mm) / Weight:(Kg) | About:1800*1000*2300// 1400kg | ||||

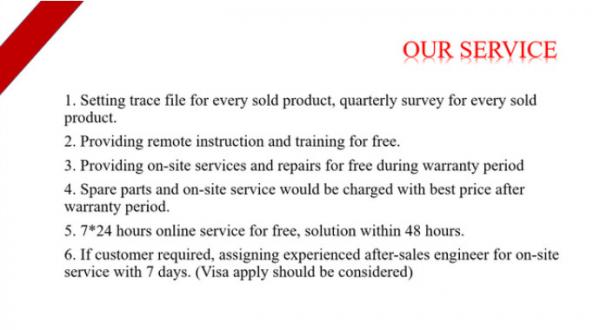

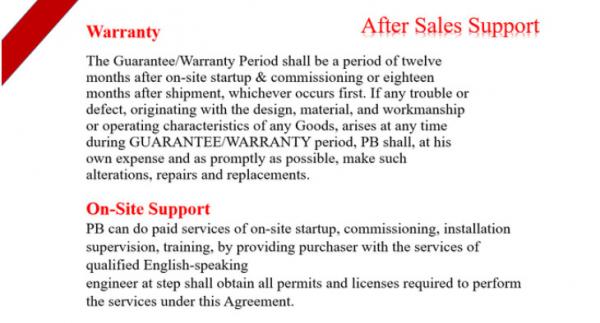

-Standard Features -

-Optional Features-

-Applications-

Ten frequently asked Questions about PSA oxygen generators

1.What is a PSA oxygen concentrator?

A PSA oxygen concentrator is a device that separates and purifies high-purity oxygen from the air using pressure swing adsorption (PSA) technology. It utilizes molecular sieve adsorbents to achieve the separation and purification of oxygen based on the differential adsorption properties of oxygen and nitrogen in the molecular sieve.

2.How does a PSA oxygen concentrator work?

The working principle of a PSA oxygen concentrator is based on the adsorption properties of the molecular sieve. It cycles compressed air and passes it through the bed of molecular sieve adsorbents. Nitrogen molecules are adsorbed onto the sieve, while oxygen molecules pass through, thereby achieving the separation and purification of oxygen.

3.What are the advantages of a PSA oxygen concentrator?

PSA oxygen concentrators have several advantages:

They can generate oxygen on-demand in real-time, eliminating the need for oxygen storage.

They are easy to operate and maintain.

They can be used indoors without the need for external gas pipelines.

They produce high-purity oxygen, suitable for medical-grade applications.

4.What are the main uses of a PSA oxygen concentrator?

PSA oxygen concentrators are widely used in medical, pharmaceutical, food processing, and electronic industries. They provide high-purity oxygen to meet the requirements of various industries and applications, such as oxygen therapy in hospitals and oxygen combustion in industries.

5.What is the oxygen purity achievable with a PSA oxygen concentrator?

6.Does a PSA oxygen concentrator require maintenance?

Yes, PSA oxygen concentrators require regular maintenance and servicing to ensure their proper operation and extended lifespan. Maintenance tasks include cleaning filters, inspecting, and replacing adsorbents, among others.

7.What is the noise level of a PSA oxygen concentrator?

PSA oxygen concentrators generally have low noise levels, typically below 50 decibels. However, the noise level may vary depending on the model and brand of the concentrator, but most are designed to operate quietly.

8.Does a PSA oxygen concentrator require a power source?

Yes, PSA oxygen concentrators require a power source to function properly. Typically, they need to be connected to a 220V AC power supply with a frequency of 50Hz.

9.Does a PSA oxygen concentrator need a compressed air source?

Yes, a PSA oxygen concentrator needs to be equipped with a compressed air source. It uses compressed air as the oxygen feedstock for its operation.

10.Is it necessary to frequently replace the adsorbents in a PSA oxygen concentrator?

Adsorbents are critical components in a PSA oxygen concentrator, and their lifespan is generally long, lasting several years. However, over time and with increased usage, the adsorbents gradually lose their effectiveness and need to be checked and replaced periodically. The specific replacement cycle depends on usage and the model of the oxygen concentrator, so it is recommended to follow the manufacturer's guidelines for proper operation.

|

|

30Nm3/H PSA Oxygen Generation Plant 93% Purity Oxygen Generating Equipment Images |